WARPING

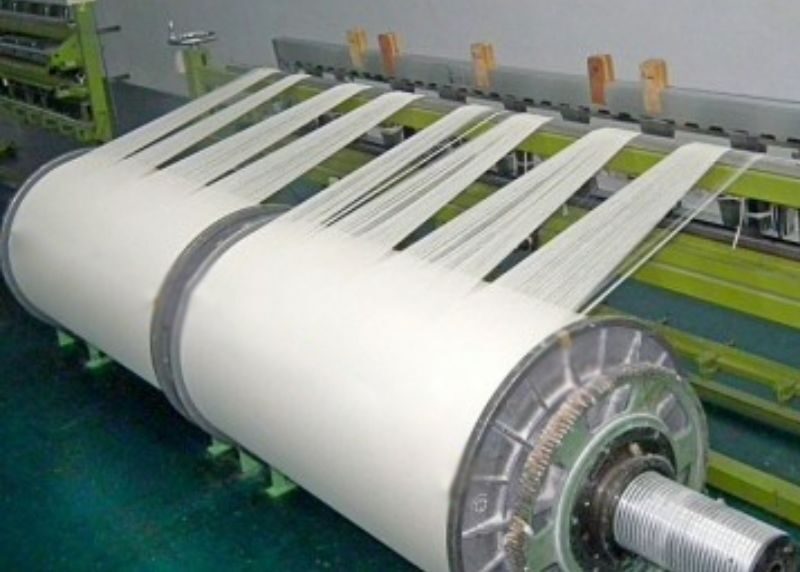

Process of weaving production begins from warping section. There fibers from a great number of reels are warping on beam roll. Process is carried out on warping machine.

2 sets of the latest warping machine model Ben Direct 1000/1800 from Benninger, Switzerland and Yunghung, Korea with maximum beaming speed of 1,200 m/min and max flange diameter of 1,016mm

SIZING

In sizing section there is drawing of a thin on a basis thread layer of gluing structure for increasing of resistibility of fibers attrition and to repeated stretching in the course of weaving. In sizing process are used both chemical and food gluing materials: as solvent water serves.

1 set of the latest high production sizing machine model S 422 from Sucker-Muller- Hacoba type WE 10 PE with maximum beam flange diameter of 1,000mm and maximum width between beam flanges of 2,300mm.

REACHING

In reaching section fibers are reached for throat formation on the machine tool and for producing of fabric set interlacing.

5 sets of the latest reaching machine model R-75, R-100S from Todo, Japan equipped with automatic sorting machine for warps with a lease and sorting capacity of 5.000 threads an hour.

WEAVING

Direct production of fabric occurs in weaving section on weaving looms. In the course of weaving as a result of a consecutive interlacing of two systems of threads - warp and weft is formed a fabric. Mills produce a gray fabric of four grades and more than 120 kinds.

100 sets of the latest weaving loom model Jat 610 with maximum width of 75 inches from Toyota, Japan equipped with 2 color at will device by electric drum pool, electronic let-off motion by AC servo motor, main control computer with 32-bit CPU, electric warp stop motion by 6- line contact bar and doublers feeler for weft stop motion.

32 sets of weaving loom model Jat 610 with maximum width of 90 inches from Toyota, Japan.

INSPECTION

Final operations of weaving production - measurement of length of fabric, cleaning and its shearing, quality assurance on inspection machine and packing on folding machine.

5 sets of the latest cloth in-grey inspecting M/C model SB-S2 from Todo, Japan with maximum roller width of 1,905 and 2,413mm.

PACKING

The finished products are neatly packaged and pressed on the press machine of the Tae Kyung, Korea model. The maximum force of the press is 250 tons.

The annual volume of weaving production makes more than 35 million running meters.